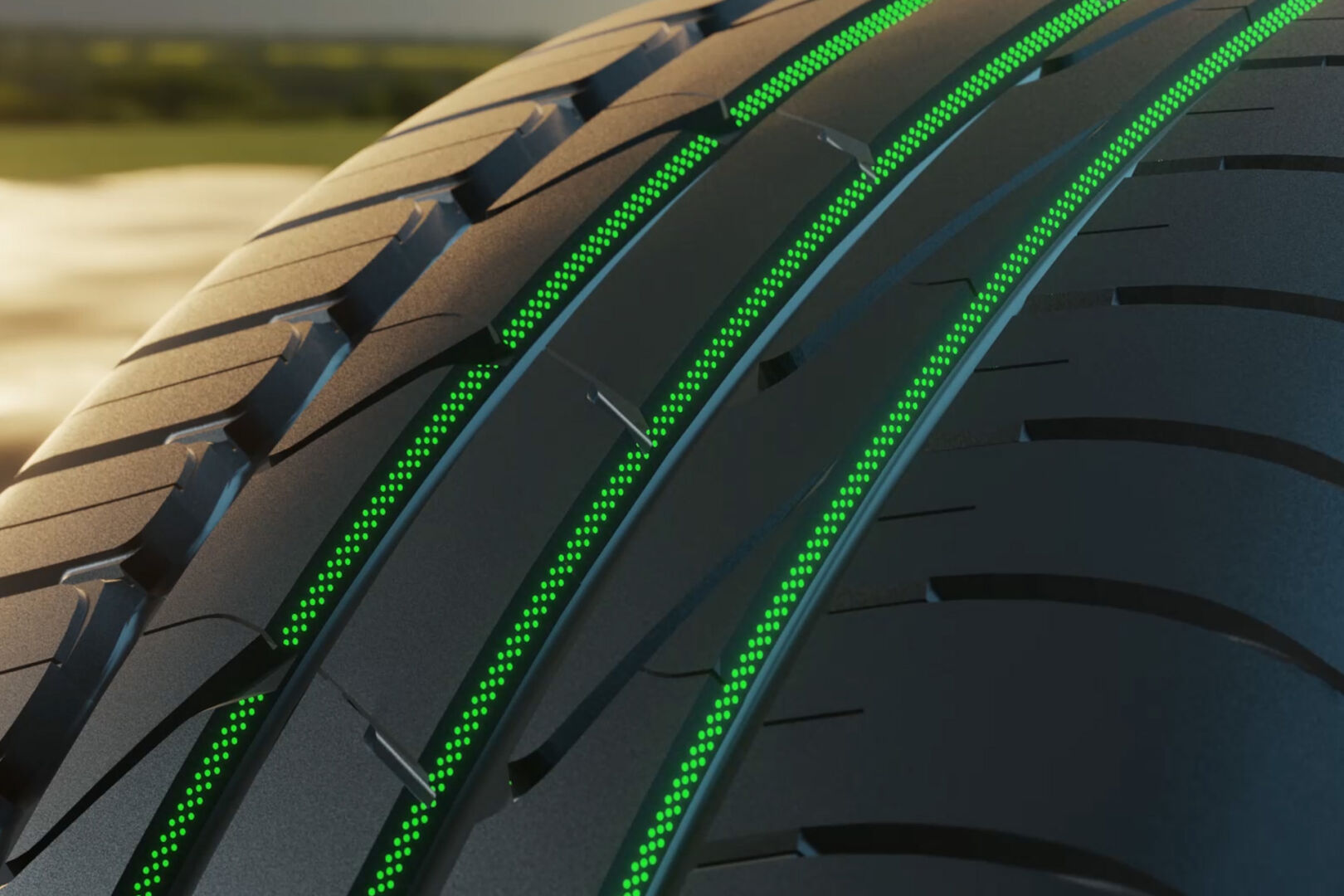

Increasing the share of recycled and renewable raw materials

Our goal is to increase the share of either recycled or renewable raw materials in tires to 50 percent by 2030, and we are actively looking for and testing renewable raw materials. Our aim is to find renewable raw materials for various raw material groups, create eco-friendlier tires, and replace fossil raw materials. We will also reduce the use of harmful substances, thereby improving occupational safety in production.

The use of new raw materials requires a great deal of product development efforts and testing to find the best combination of properties for a tire, as new raw materials can modify the compound properties. In materials development, the use of renewable materials must not alter a tire’s safety characteristics. The choice of new materials can also be affected by the material not being fossil based, as that makes the material a more sustainable option.

We were the first in the industry to give up the use of harmful HA (high-aromatic) oils in production. The global research of oils and resins from renewable sources to replace the low PAH content oils is active, but their commercial availability is still limited in the tire industry. Nokian Tyres has an active role in this constantly evolving research and industrialization process. We are already using renewable oils such as rape seed oil and tall oil in our rubber compounds and we continue to research them. Our work to increase the renewable oil content in our rubber compounds is aligned with our goal of increasing the share of renewable and recycled raw materials in our tires to 50 percent by 2030.

Fillers, mainly carbon black and silica, are one of the main raw material groups in a tire. The share of fillers is around 28 percent in a tire, meaning that, in theory, it should be possible to increase the ratio of recycled or renewable raw materials significantly by substituting fossil-based fillers with ones from either recycled or renewable sources.

One type of recycled filler material source is rubber retrieved from used tires. We have also actively researched the use of recycled carbon black in tires. Securing the availability and research of several grades of recycled carbon black has proven to be a task that needs effort, but there are now more raw material providers on the market, and Nokian Tyres has several ongoing projects on the matter. An example of a successful project was when, in line with the company’s goals, recycled carbon black was included in a commercial product line during 2022.

Our passenger car tire factories in Finland and Romania are ISCC PLUS certified, which also helps us reach our 2030 target. We're aiming to increase the share of sustainable, ISCC PLUS certified raw materials in our tires yearly.

Tire materials and their alternatives

Material | % of a tire (approximately) | Sources | Replacements and alternatives |

Synthetic rubber | 23 | Crude oil | • Polymers from renewable sources • Mass-balance approach • Recycled rubber crumbs |

Natural rubber | 22 | Natural rubber | • Guayule as an alternative for natural rubber • Recycled rubber crumbs |

Fillers | 28 | Silica, carbon black | • More extensive use of recycled carbon black is under investigation • Active research of different renewable fillers, for instance forest industry’s side stream-based materials |

Reinforcement materials | 15 | Steel, textile | • Recycled steel is used in reinforcement materials • Increasing the share of recycled steel in reinforcement materials is being researched • Researching the use of renewable or recycled sources for textiles |

Chemicals | 12 | Several sources | • Increasing renewable or recycled oil and resin content in tires • Reduction and elimination of harmful chemicals and search of alternative options from either recycled or renewable resources |

Assessing the sustainability of raw materials

We have assessed the sustainability-related risks associated with different raw material categories. The assessment is based on Nokian Tyres' knowledge on raw material commodity risks and information gathered from suppliers. The risk classification scale is Insignificant, Minor, Moderate, Major, Significant. If a risk is identified as significant, it is also included in corporate ESG risk assessment.

| Raw material category | GHG emissions | Share of volume | Local pollution (water, soil, waste handling, air) | Social | Use of virgin non-renewable resources | Biodiversity and deforestation | Ongoing and planned actions |

| Natural Rubber | 20-25% | Minor | Moderate/Major | Major | Insignificant | Major | EUDR-compliant rubber, GPSNR co-operation, 3rd party audits |

| Synthetic Polymers | 20-25% | Major | Moderate | Minor | Major | Insignificant | Requesting improvements, prioritizing low-emission, renewable and recycled alternatives |

Carbon black & Silica | 25-30% | Moderate | Moderate | Minor | Major Moderate/Major | Insignificant Minor | Requesting improvements, prioritizing low-emission, renewable and recycled alternatives |

Steel & Textiles | 10-15% | Moderate Major | Moderate | Minor | Moderate/Major | Minor Insignificant | Requesting improvements, prioritizing low-emission, renewable and recycled alternatives |

| Chemicals | 10-15% | Moderate | Moderate/Major | Minor | Moderate/Major | Minor | Requesting improvements, prioritizing low-emission, renewable and recycled alternatives |