Lead to Circularity

Targeting a tire made entirely from recycled and renewable materials

What is the challenge we are solving?

Tires are traditionally made of various different materials that are environmentally problematic in terms of their origin, recyclability, and particle emissions. The key task for Nokian Tyres in the promotion of the circular economy is to be involved in the development of new, innovative raw materials, to extend the life cycle of tires, and to improve the recycling of materials. Through this work, we want to create new and better material streams as well as ways of working for the entire industry.

What are we aiming for?

Nokian Tyres’ product development is based on continuous improvement of safety and environmental factors.These principles guide everything that we do. Our target is to increase the share of recycled or renewable raw materials in tires to 50 per cent by 2030. At the moment, we are halfway to meeting our goal.

Even though our plans related to the circular economy are among the most ambitious in the industry, to us they are a logical continuation of the work that we have been doing for a long time. We were the first tire manufacturer to switch to purified oils in production, already achieving this in the early 2000s. At the same time, we started using recycled raw materials in our production by replacing the harmful high aromatic oils used in winter tires with canola oil.

What will it take to meet the target?

New innovations in materials

Rubber, carbon black, steel, and specific chemicals have traditionally been key manufacturing materials for tires. At the moment, pioneers in the tire industry are seeking renewable and recycled alternatives for these fossil-based and virgin raw materials in order to reduce the environmental impacts.

No individual material can solve this challenge; instead, the key is to examine many alternative approaches and to seek solutions across industry boundaries. Nokian Tyres has been utilizing recycled rubber, carbon black, and steel in its products for a long time, and we introduced a concept tire containing 93 percent recycled and renewable materials already in 2022.

In June 2024, we introduced the new Nokian Tyres Green Step Ligna concept tire that was manufactured using a patented, fully renewable lignin raw material produced by UPM. Under a second line of investigation, we are working with a partner to refine leftover birch bark from the forest industry into a raw material for tires that can replace traditional, fossil-based materials. The target is that these renewable materials will also improve tire performance. In addition to the above, we are also researching the utilization of other industrial waste streams. A good example of this is rice husk ash that can be used as tire filler material instead of fossil-based carbon black, for example.

By setting an example, we are aiming at virgin fossil raw materials being eliminated from the tire industry within the next couple of decades.

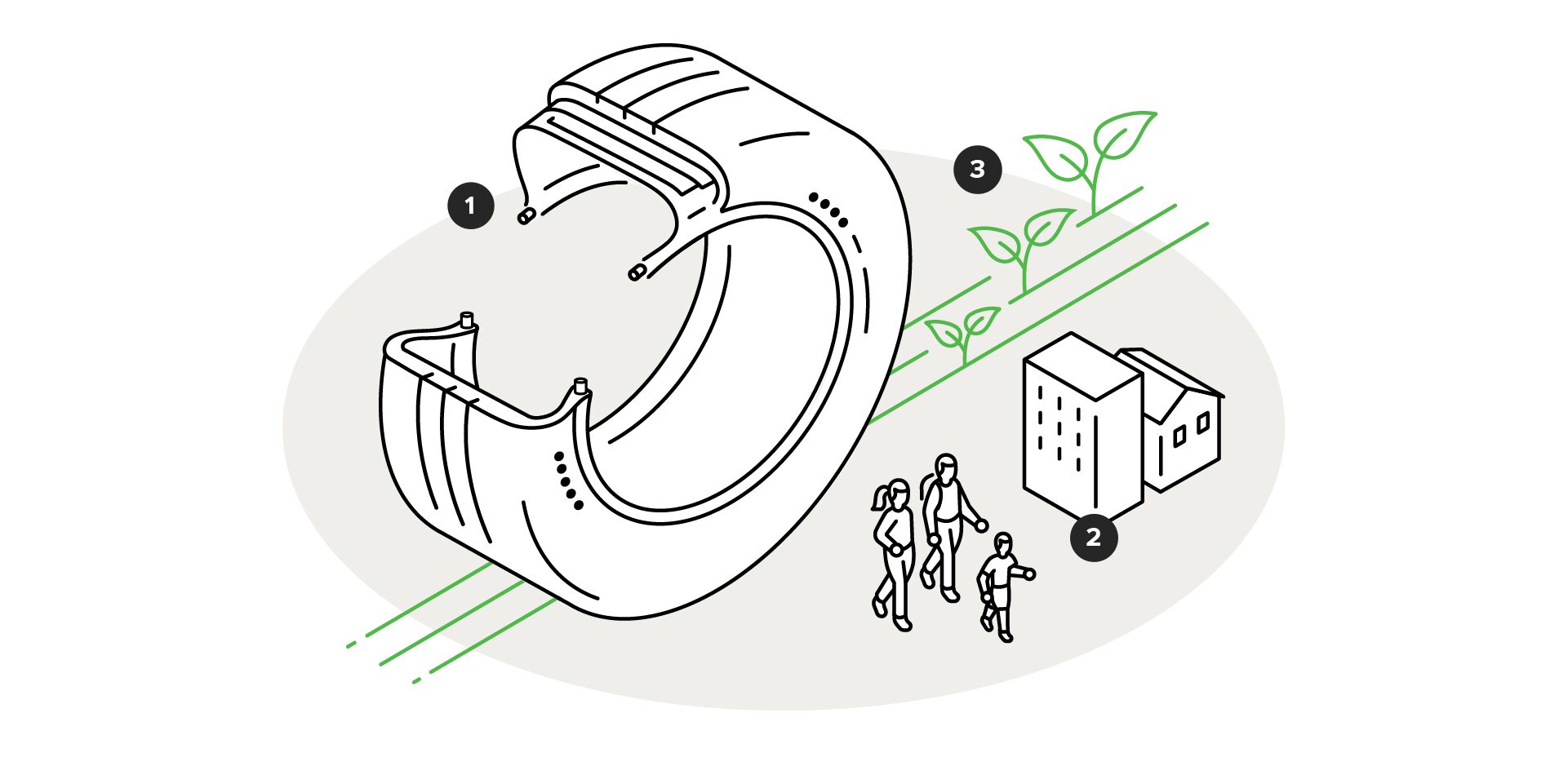

On a journey toward a smaller environmental footprint

1. Developing materials

We are continuously seeking renewable and recycled alternatives for fossil-based and virgin raw materials in order to reduce the environmental impacts.

2. Advancing together

Collaborations will help us eliminate virgin fossil raw materials from the tire industry within the next couple of decades.

3. Driving responsibility

One of our key non-financial target is to increase the share of recycled and renewable raw materials in our tires to 50 percent by 2030.

Increasing the recycling rate and the utilization of waste streams

Tire manufacturing is a complex process: some hundred ingredients are bound together using a method referred to as vulcanization, where the green tire is cured at a high temperature and pressed against the mold at high pressure. While vulcanization is vital in order to reach the tire’s ideal characteristics, it is also one of the largest environmental challenges faced by the tire industry: Once a product has been made, returning it to raw materials will be very challenging.

Nokian Tyres supports research that seeks solutions for devulcanization and the more exact separation of the tire’s polymers. Potential new innovations allow for the materials in tires to be recovered for reuse at a higher level of purity.

Typically, the life cycle of a tire lasts for some six years, depending on the degree of use and the user. The future holds a potential revolution in this respect, as the retreading of tires and new, more durable raw materials might make it possible to triple the service life of tires. At the present time, the variation in the level of recycling between different countries is a key challenge within the industry. In Finland, all end-of-life tires are recycled, whereas in the United States, the figure is only around 80 percent – and it is even lower than this in many other countries. We want to take action in order to promote a value chain for tires past the end of their service life and the creation of new business opportunities.

Improving wear resistance

Tire wear or abrasion is a phenomenon that occurs because of the friction needed for the vehicle to remain safely on the road. This interaction between the road and tire generates tire and road wear particles (Tire and road wear particles, TRWP) that are generally considered to be microplastics, which are detrimental to the environment due to their size and composition. The tire industry alone cannot solve the detrimental environmental impacts from the particles, but in our role, it is essential that we try to measure and minimize them.

Nokian Tyres develops tires for the world’s most challenging conditions and for increasingly heavier vehicles, and so it is important for us to understand how varying road surfaces and speeds, on the one hand, and tire characteristics, on the other hand, will affect tire wear. Based on our experience, improving wear resistance is a key tool for reducing particulate emissions. We are continuously developing tire designs and material combinations that slow down tire wear without reducing friction, which is required to guarantee safety.

Developing standards for measurement is another key tool for reducing particulate emissions. The lack of global test methods is a challenge to the entire industry. This is why Nokian Tyres is taking an active role in the International Organization for Standardization (ISO) that creates common methods for measuring TRWP emissions. This understanding enables us to offer authorities and other stakeholders’ insight into what the entire industry should aim for.