Article

Studs grip the road

Studs are the superior safety accessories for increasing grip in icy weather. They are a Finnish innovation that has evolved along with the development of the roads and cars. Modern studs are an undeniable safety feature under the right conditions. The driver can rely on the ever-improving stud technology that takes safety, the environment and driving comfort into account.

The tread pattern of the first Hakkapeliittas was designed for snowy weather. As the number of cars increased and road maintenance improved, the winter driving conditions also changed: there was a lot of traffic and ploughed road surfaces became icy. At the turn of the 1960s, developing a skid stopper between the tire and the road in order to improve the grip of the winter tire tread.

There were many different ideas. Several suggestions were made concerning how to make the tires grip better; among these were rubber linings with metal sleeves and tread compounds containing ceramic pieces. There were several different types of metallic slide stoppers on offer, such as riveted tires and tires with different springs and spikes.

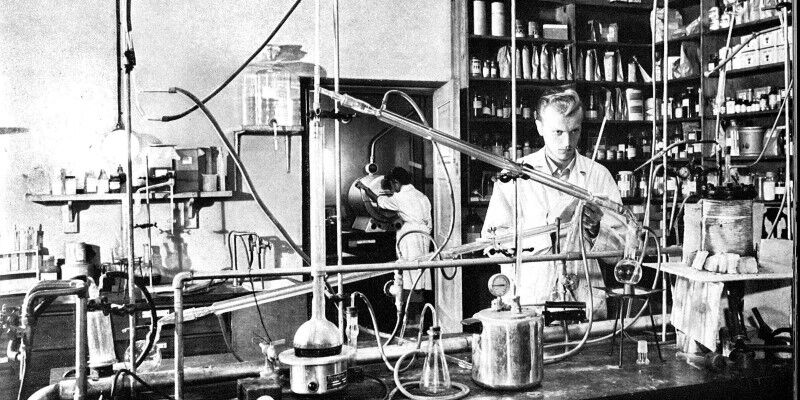

Veikko Ryhönen, inventor of the stud

The hard metal studs embedded in the tread of the winter tire originated from an idea by Veikko Ryhönen, a rubber repairman from Varkaus. Ryhönen worked as a supervisor at Arkela Oy’s rubber workshop and realised how the skid stopper could be fastened to the tire tread. This would require pushing a metal rivet with a mushroom-type stem into a tight hole drilled on the surface of a rubber tire. In 1957, Ryhönen applied for a patent for his invention called “Piikkirengas” (Spiked tire). The patent was finally granted in 1959. The application indicates that Ryhönen used a Hakkapeliitta winter tire in his tests.

Image: Veikko Ryhönen

Stud inventor Ryhönen and the Kometa-Hakkapeliitta

Supervisor Veikko Ryhönen from the Arkela rubber workshop in Varkaus can be considered to be the inventor of the modern tire stud. He was already developing spikes that improve tire grip in the 1940s. Ryhönen patented his invention in 1959.

The breakthrough product for the consumer market was Kovametalli Oy’s Kometa stud, whose power and durability were based on a hard metal tip. Cooperation with Suomen Gummitehdas created the Kometa-Hakkapeliitta, a winter tire designed for studding. It was a solution for modern winter roads: the stud grips on ice, while the tire itself handles soft surfaces.

At first, the tires and studs were sold separately. In order to ensure that studs were installed correctly, Suomen Gummitehdas started manufacturing Haka-Hakkapeliittas with ready-made stud holes and left the installation to a professional tire dealership.

Kometa-Hakkapeliitta - the studded warrior

The problem with the new and patented skid stopper was that the tip of the stud wore out quickly. When the Finnish Oy Kovametalli Ab combined the stud innovation with a hard metal, this created the unique hard metal stud: a rivet with a steel body received a soldered hard metal core. The wear resistance was optimised to match the rubber tread.

Factory-studded hakkapeliittas

It was not always clear for drivers as to how they should equip their vehicle for winter traffic. The tire company campaigned for correct installation: professionally studded tires for every wheel! The use of studded tires was under heavy discussion in the Nordic countries, but the results spoke for themselves fairly quickly and studded winter tires became the primary weapon against slippery weather. In Finland, for example, four out of five users of winter tires chose studs in the mid-1960s.

1964 saw the launch of the world’s first special tire designed for studding, simply called Hakkapeliitta. The very next year, all Hakkapeliitta sizes were available with stud holes. By the time that radial winter tires became the norm in the mid-1970s, factory-studded tires were already the most popular type. The most important benefits of studded winter tires were that braking distances became shorter and steering could be maintained even on icy road surfaces.

Haka-Hakkapeliitta

The Haka-Hakkapeliitta was the best-selling winter tire of the 1950s and 1960s. The range of Haka-Hakkapeliittas that was launched in 1956 and grew to a full size selection two years later was the answer to the new winter driving conditions and even larger cars. The tread had a dense pattern of protrusions that proved effective on icy roads with packed snow, since braking caused a small air pocket to form between the protrusion and the road surface, resulting in suction cup-like grip. The longitudinal grooves on both sides of the centre area were also a new feature of the Haka-Hakkapeliitta. They ensured good directional stability.

Image: The Haka-Hakkapeliitta, a new product launched in 1956, beat all previous sales records.

Non-studded winter tires enter the market

Initially, the legislation in different countries differed as regards the use of skid stoppers in road traffic. In Finland, the home of the winter tire, new studded tire regulations were introduced in the 1970s in order to control road wear. The stud protrusion was set at 1.5 mm for passenger cars and their number and force were limited. The usage period for skid stoppers was set to be from mid-October until April.

Due to the energy crisis, economical driving and the effects of studs on the tire’s rolling resistance were the key development challenges in the 1970s. In the 1980s, the development of stud technology focused on improving handling and driving comfort: radial tires and even more powerful cars required the stud to roll lightly as well. Stud size was reduced and the tip was rounded.

By the 1990s, winter driving involved plenty of motorway sections and the roads were often bare. The time was right for a non-studded winter tire. These tires eliminated the studs but maintained the high-quality rubber compounds and tread patterns that kept the vehicle on the road.

The first non-studded Hakkapeliitta came out in 1991. The non-studded option of the 1996 Hakkapeliitta series, the Nokian Hakkapeliitta NRW 1, was a new-generation non-studded tire that improved the wet grip, ice grip and wear resistance of the tire at the same time.

The new Hakkapeliitta

The invention of the stud started a new era in winter driving that revolutionised the entire design of the winter tire. Suomen Kumitehdas wanted to offer drivers a modern and safe alternative. The Hakkapeliitta developed in 1964 was the first of its kind, a winter tire that had been designed for studding from the beginning.

Image: Hakkapeliitta with rally studs. There are stud holes on every row.

Square stud, eco stud and bear claw

From the 1990s onwards, the traditional round stud body became square. A square stud also has a square bottom flange and the hard metal stud pin, which improves the durability and guarantees excellent grip on ice.

The Nokian Eco Stud anchor stud was launched in 1995. This light stud pushed out of a hole that was designed to act as a damper and locked itself into place. The stud cushion dampened the impact and improved the operation of the stud. In addition to eco-friendliness, the new stud technology offered firm stud adhesion and low rolling noise. The latest version of the adaptable and highly controllable stud technology is the Eco Stud 8 concept introduced in 2013. It includes all of the advances in stud design: a multi-faceted anchor stud, flange design that reduces impact and the patented stud cushion.

The development of non-studded winter tires also needed to take into account the safety characteristics of the new, high-performance car models, such as ABS brakes and the traction control and stability control systems that were developed on the basis of this technology. For example, the Nokian Hakkapeliitta RSi (2003) offered a new speed rating and had brake boosters in its tread that allowed for even more stable grip during acceleration and braking.

The Nokian Hakkapeliitta 5 studded tire from 2006 introduced the Bear Claw that assists the stud. This innovation refers to a claw on the front edge of the tread blocks that keeps the stud in an optimal position during braking. This ensures immediate grip effect and stable handling.

Eco stud system

Studs wear out asphalt, which is already under heavy stress under Northern conditions. This fact was used as a justification by many who had a critical opinion towards studs, all the way from the discussions in the 1960s. Nokian Tyres, not content with merely pondering the situation, took steps to find solutions that would generate less wear. One of the more far-reaching innovations was the Eco Stud System launched in 1995.

Stud holes

Preparing stud holes in the tire tread was a substantial advance in the durability and safety of the studded tire. This meant that the quality of the rubber was no longer reduced by stud holes that were drilled afterwards. Studs that were installed in ready-made holes were oriented precisely perpendicular to the tread and their protrusion was even.

The secret of grip

The secret behind the grip is the stud impact, but this is also a factor that increases rolling noise and road wear. The Hakkapeliitta 7 studded tire that was introduced in 2009 used Air Claw technology that works similarly to running shoes with air cushions. The tread block has an air pocket in front of the stud that dampens the road impact during the contact and release stage. This reduces wear on the road surface and the stud itself and maintains rolling noise at a comfortable level.

The tread of a modern studded tire works seamlessly together with the studded technology. Sipes that improve the grip of the tread also support the operation of the stud. The Driving Safety Indicator (DSI) patented by Nokian Tyres provides the driver with information concerning tire wear.

The rubber compound of the tire safely adapts to different weathers and temperatures. In the latest winter compound, the proportion of natural rubber has increased to 20%. Nokian Cryo Crystal grip particles were added to the rubber compound of the non-studded winter tire in 2014.

Driving safety indicator

You can easily check the tire’s remaining service life by using the Driving Safety Indicator that can be found in both winter and summer tires. The numbers on the middle of the tire tread disappear one by one as the tire wears down. For winter tires, the critical wear point is also marked with a snowflake. When the snowflake has worn off, the time has come to buy new winter tires. Nokian Tyres patented the Driving Safety Indicator in 1999.

The hybrid tire of the future

The updated flagship of stud technology is the Nokian Eco Stud 8 concept that provided winter grip like never before for the Nokian Hakkapeliitta 8 in 2013. The changes in studding in the Hakkapeliitta 8 were so unique that new, bespoke studding machines were required for the tire model.

The new feature was the optimal stud placement: instead of the standard shoulder area, studs were placed evenly across the entire tread surface. The idea was that no stud is behind another, which ensures the best possible grip in any situation. Furthermore, the number of studs returned to the high level where it was when the studded tire was first born: Nokian Hakkapeliitta 8 has up to 190 studs. However, the familiar Eco Stud cushion makes road contact so sensitive that road wear is well below the legislative limits. The studs of the new Hakkapeliittas weigh less than one gram per piece. When new, their protrusion is 0.8–0.9 mm.

In 2014, we received a glimpse of the future of the studded tire when Nokian Tyres introduced a revolutionary hybrid tire that allows the driver to activate the studs at the press of a button. So far, this model is only a concept tire, but it shows how the non-studded and studded properties of the tire can be used according to the changing weather conditions. This combines the best innovations of non-studded and studded tire technology and ensures safe winter driving under all conditions. The grip champion between the tire and the road has undergone several stages of development and is once again ready for new challenges.

Cryo crystal grip particles

The skid stopper can also be inside the rubber compound! Microscopic, chamfered crystals added into the rubber compound of the non-studded winter tire improve its lateral and longitudinal grip especially on ice. The diamond-tough Cryo Crystal particles grab onto the driving surface and improve grip. New crystals will continuously start to appear as the surface of the tire wears down.

Image: Nokian Cryo Crystal Concept. In a way, the crystals act as built-in studs by gripping the surface with their sharp and hard edges.