Article

Relentless product development

In product development, research and testing have played a key role throughout the history of Nokian Tyres. Expertise, relentless work, and persistence combined with a search for entirely new solutions have been defining features, both in the laboratories and on the test tracks.

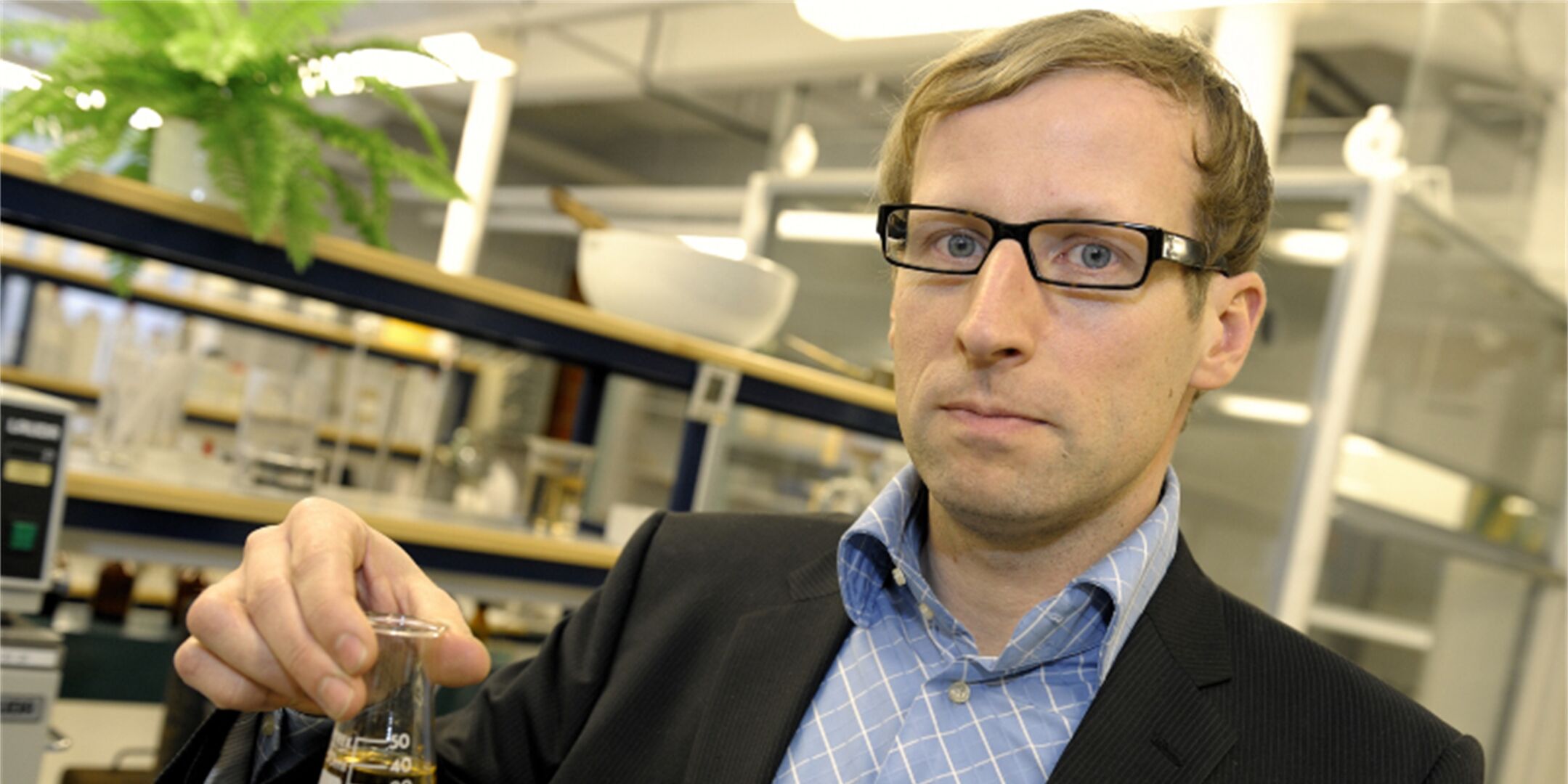

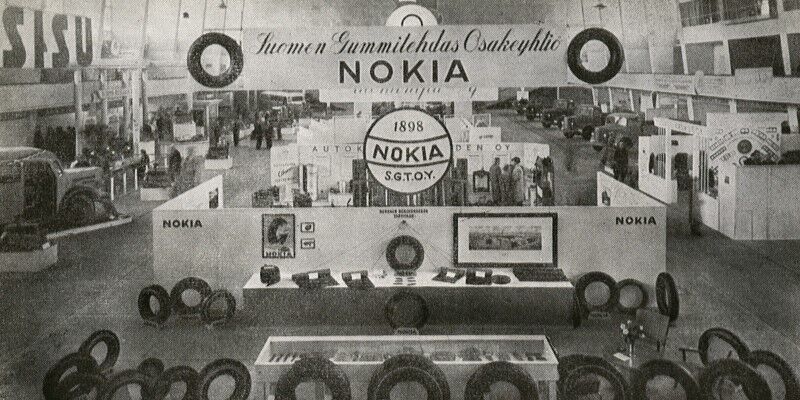

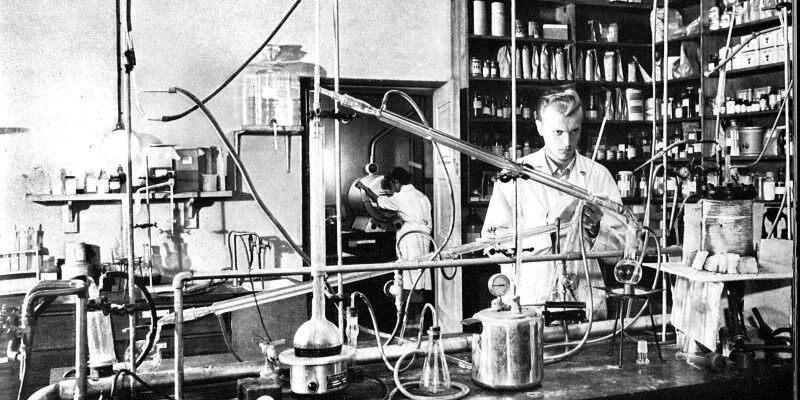

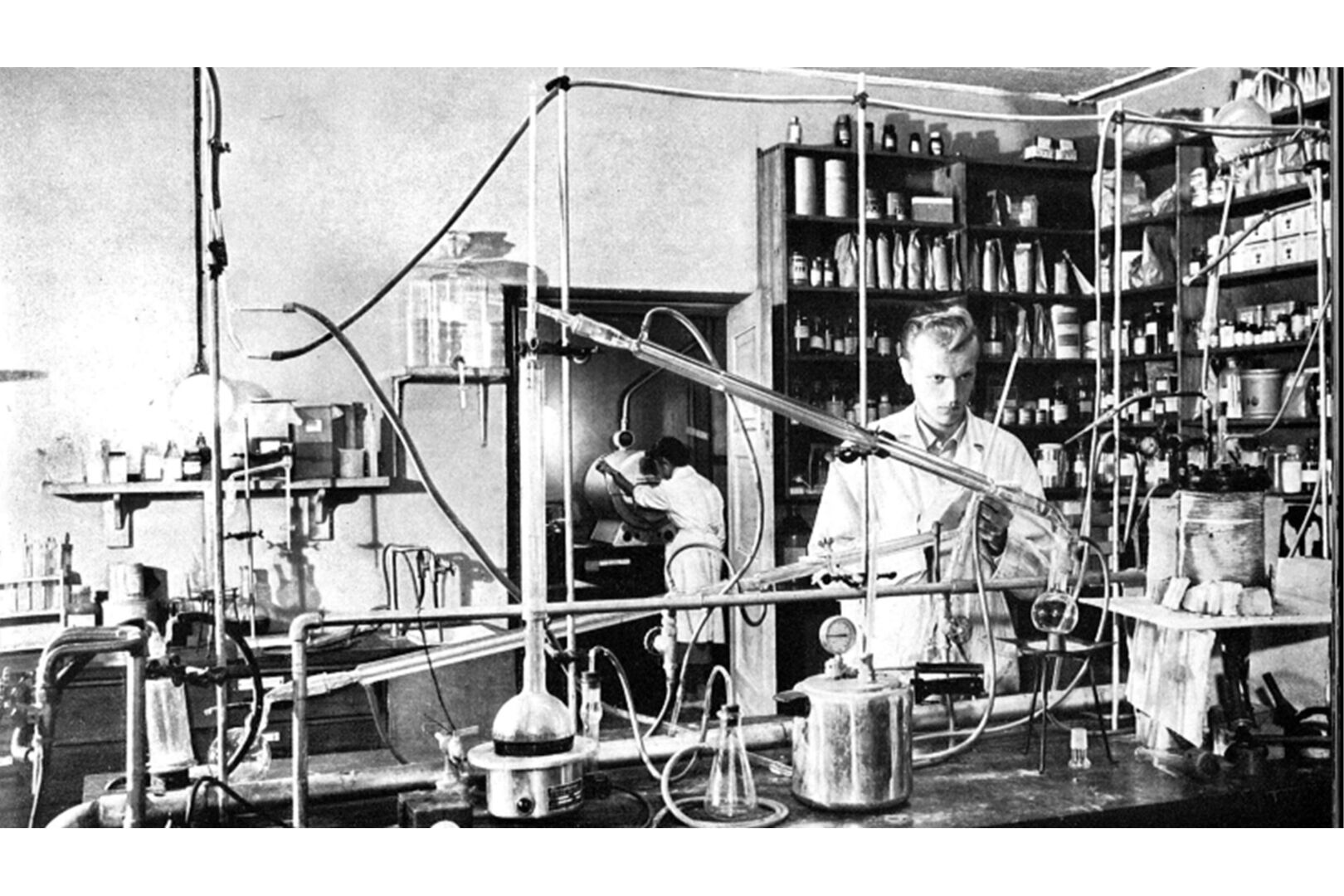

The Suomen Gummitehdas laboratory was established in 1920, at the initiative of technical director Antti Ahtero. Gustaf Komppa, one of the leading chemists in Finland, was also part of the factory board of directors. The facility located in Helsinki later became the Keskuskumilaboratorio (Central Rubber Laboratory) that researched raw materials and developed compounds for all the fields of business at Gummitehdas.

The tire department also conducted in-house research. Manufactured tires were actively tested by bus lines, such as the Paunu service between Tampere and Nokia, and the service to Helsinki of Leino & Kumppani. Taxi drivers were also used as test drivers for tires.

Research activities at Gummitehdas further developed especially during the exceptional conditions of World War II, with research conducted in the fields of domestic synthetic compounds and rubber dandelion cultivation.

Keskuskumilaboratorio

Suomen Gummitehdas Osakeyhtiö organised its product development activities in 1920, when the company's first technical director Antti Antero established the Keskuskumilaboratorio (Central Rubber Laboratory) in Helsinki. The Baltic German Paul Zilchert was appointed as the manager.

Wonders of the tire laboratory

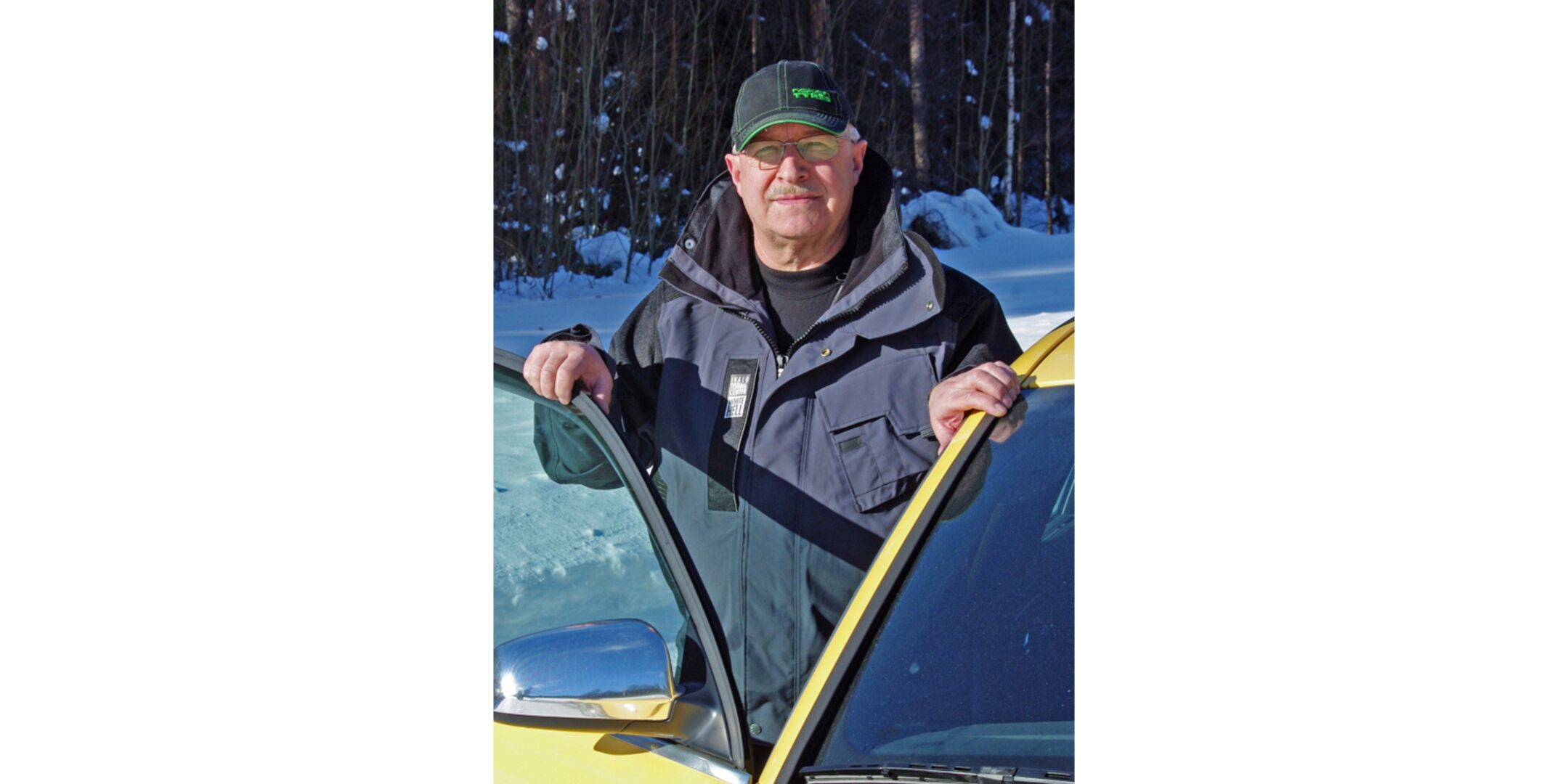

In the 1960s, new winter tire innovations increased the need for test driving. Taxi drivers from Tampere were used to test the durability of studs. In total, professional drivers completed over fifteen million kilometres per year in monitored field tests using tires from Nokia. The cars were inspected once a month and the drivers were interviewed at the same time.

The tire factory gained its own R&D department in September 1969. The tyre laboratory invested in three-slot testing machines that could be used to measure rolling resistance or rim attachment up to a speed of 250 kilometres per hour.

Rubber dandelion

To reduce the material shortage during the war, Finland tried to extract domestic natural rubber from rubber dandelions (Taraxacum kok-saghyz). The cultivation test that started in the summer of 1943 was led by Professor Otto Valle from the Maatalouskoelaitos agricultural experiments laboratory in Tikkurila and plantations of 1 to 10 acres were located across the country. Even Nokia had its own dandelion plantation.

Hakkapeliittas on the track

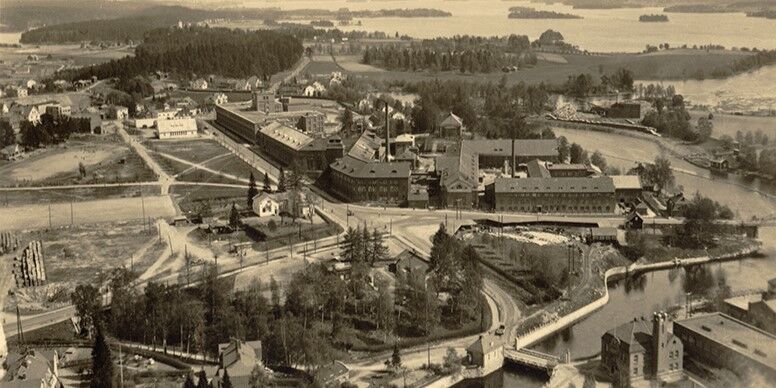

The winter characteristics of Hakkapeliittas were measured on the 1.2-kilometre ice track on Alisenjärvi in Nokia, which was completed in 1968. The measurements were made using Peiseler equipment, but the car types varied.

The next year, the company acquired and hired its own cars and drivers. Two Saab 99 passenger cars drove approximately 1,300 kilometres per day, in two shifts. The first driving crew consisted of Pertti Niikkonen, Jaakko Aho, Matti Puuska, and Jarmo Takkinen. A total of 400,000 kilometres were accumulated each year until October 1970 when the cars were replaced by Volvos. The Tire test sign became a familiar sight in Nokia. Currently, the Nokia testing centre is the heart of summer tire product development. On the Nokia, company simulates almost all driving situations on northern roads. Demanding conditions are sought around the world, when necessary. Tests for the UHP tires intended for high-speed driving are performed on test tracks abroad.

Nokia testing centre

The nearest testing centre of the company is located around the corner from the Nokian Tyres headquarters. The test track in Nokia was originally built in the 1960s, and has now expanded to 30 hectares in size. One of the latest expansion was completed in 1999, and it brought variety especially to the high-speed tests. Testing in Nokia is performed from spring to late autumn. In addition to the versatile handling tracks, product development engineers have access to an automatic rain-making system and a high speed camera, for example. Nokian Tyres is also a pioneer in slush testing. Slush planing tests for started on the Nokia track already in 1996.

Image: Nokian test track 2015

Expert in northern conditions

Friction tires were on the upswing internationally at the end of the 1970s. Locations for testing the Hakkapeliittas in winter conditions were sought all over the country. In 1986, the company founded its own, fixed testing centre in Ivalo, north of the Arctic Circle, where R&D and testing teams as well as test divers put tires to a trial with the task of separating the best tires out of a good selection. The company is the world's leading expert in northern conditions especially due to the comprehensive and careful testing performed in Lapland.

The centre, which has expanded to over 700 hectares, is used for demanding winter testing from October to May.

The increasingly varying winter conditions required the further development of the test methods. The new generation of Hakkapeliittas underwent slush planing tests, for example, which Nokian Tyres was the first in the world to introduce in 1996.

Ivalo testing centre

Testing winter tires in actual conditions is an essential condition for product development. Throughout its history, Nokian Tyres has taken advantage of the Finnish weather and demanding winter conditions. Starting from the 1930s, the Hakkapeliittas were mainly being tested around Nokia. In the 1970s, the testers and their cars started moving further north. Each winter, suitable test conditions were sought at different locations. This always involved heavy transport and establishing a testing base, and the weather and testing opportunities could change at any time.

Tailored products for different markets

Developing tires requires careful, focused planning. Different markets require their own tailored products and precision innovations. Markets and consumer groups are becoming increasingly fractured. Product development carefully follows the movements and changes of consumer needs, and tries to anticipate user wishes. The market can be convinced by offering products that have been carefully tailored for different uses and that have passed strict testing requirements.

Nokian Tyres uses about half of its R&D costs on testing products. Sufficient test results cannot be achieved under laboratory conditions alone. Therefore, Nokian Tyres tests its products under authentic conditions around the world in order to make them work flawlessly under difficult, demanding and varying conditions.

Its own test laboratory in Ivalo, Finnish Lapland, develops test winner tires that consumers around the world can rely on. Test winners are created through high-class expertise and millions of test kilometres.

The multiple test-winning Nokian Hakkapeliitta 8 studded tires achieved the latest world record for the fastest car on ice, 335.713 km/h (208.602 mph).

Testing at the extremes

In recent years, Nokian Tyres has dominated the world records for the fastest car on ice. Test driver Janne Laitinen clocked the latest record of 335.713 km/h (208.602 mph) in March 2013 on the ice of the Gulf of Bothnia, near Oulu. The car was an Audi RS6 equipped with Nokian Hakkapeliitta 8 studded tires. At the record speed, the car travelled over 93 metres per second. The earlier record was also set by Laitinen: 331.61 km/h (206.05 mph).