Article

1940: Military service

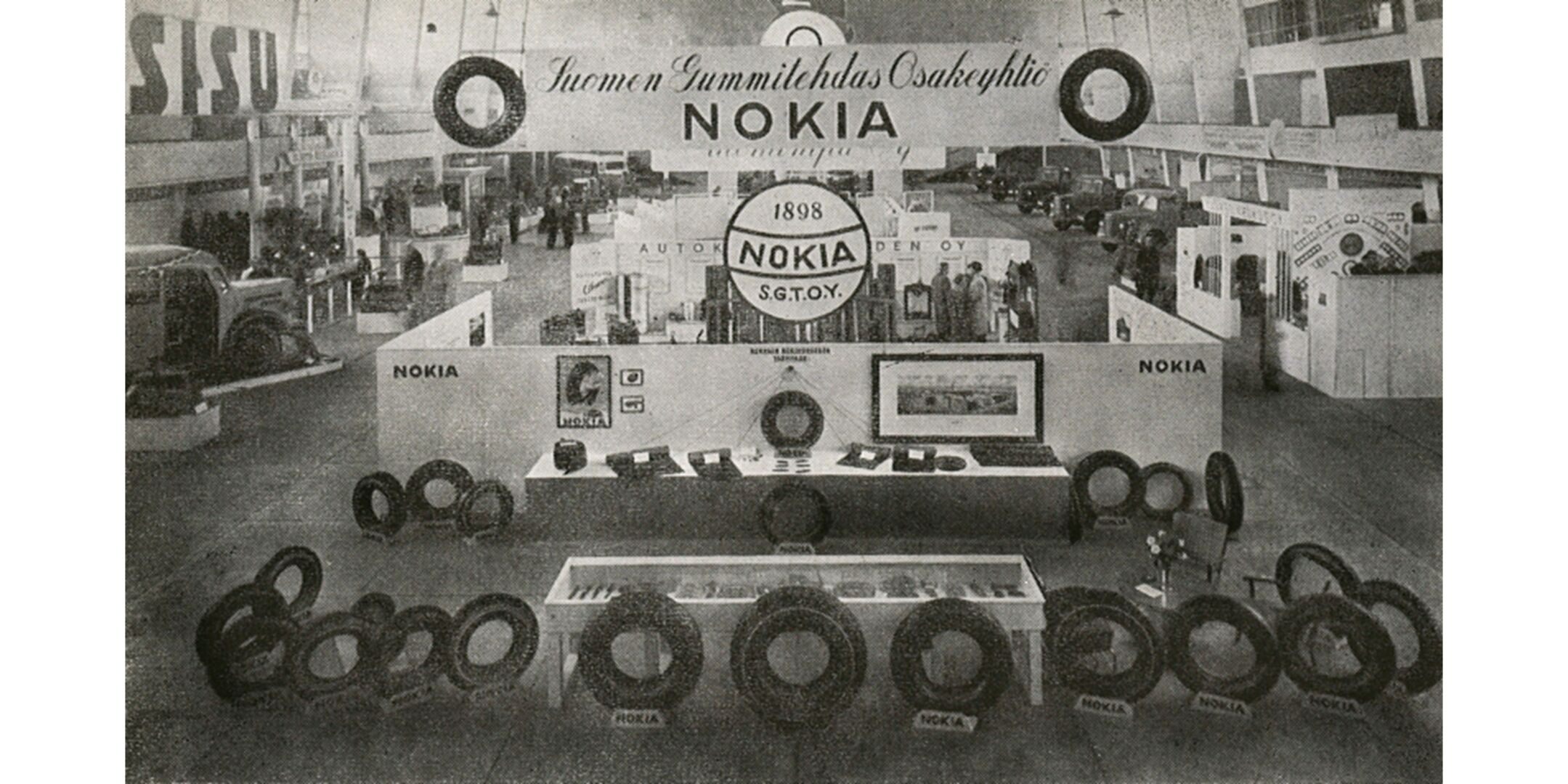

During the Winter War and the Continuation War, Suomen Gummitehdas focused on the needs of the Finnish Defence Forces, with truck tires and special products taking a leading role. The only tire factory in the country was essential for the war effort. Paavo tires for horse-drawn carts were especially important on the front. When carts were equipped with rubber wheels, troops could be supplied quietly all the way to the front lines.

Winter tires for every road

When the Hakkapeliitta was born, buses and trucks worked especially hard in traffic. This became even more important during the war, and goods transport ruled the roads until the end of World War II. A reliable winter tire was in demand for many different kinds of special vehicles, such as fire engines, logging trucks and snow ploughs. The mantle of the Kelirengas, which was designed for trucks, was successfully passed on to the Hakkapeliitta for trucks that was designed in 1940.

Image: Truck winter tire in action in Kainuu, Finland. Trucks replaced horses in log transport after World War II.

Gummitehdas also joined forces with Suomen Kaapelitehdas to donate an American Brewster fighter plane to the Finnish Defence Forces. The plane, BW355, was nicknamed “Noka”.

Special product for fighters and bombers

During the war, Suomen Gummitehdas supplied products to the Finnish Air Force. The Valtion Lentokonetehdas aircraft factory, operating in Tampere, was looking for a tire to be used as a tailwheel for an aircraft. The person making the query was doubting the availability, but Senior Engineer Ensio Salmenkallio from the Gummitehdas tyre department only wanted to know the required size and delivered a suitable tire immediately. This was a pushcart tyre of size 12x4. Tires from Nokia provided many take-offs and landings for Finnish aircraft as well as the Blenheims, Brewsters and Messerschmitts.

The shortage of raw materials and delivery problems created a need for substitute materials. Butadiene rubber, or Buna, was received from Germany. The American equivalent was GR-S (Government Rubber Styrene). Synthetic rubber had poorer frost resistance and flexibility than natural rubber. A Finnish synthetic rubber compound was also under development, with experiments in the field of rubber dandelion cultivation.

There was also a shortage of chemicals, such as carbon black. The recipes had to be adapted to the available materials, which caused the compounds to change even before any driving experience was available.

Rubber dandelion

To reduce the material shortage during the war, Finland tried to extract domestic natural rubber from rubber dandelions (Taraxacum kok-saghyz). The cultivation test that started in the summer of 1943 was led by Professor Otto Valle from the Maatalouskoelaitos agricultural experiments laboratory in Tikkurila and plantations of 1 to 10 acres were located across the country. Even Nokia had its own dandelion plantation.

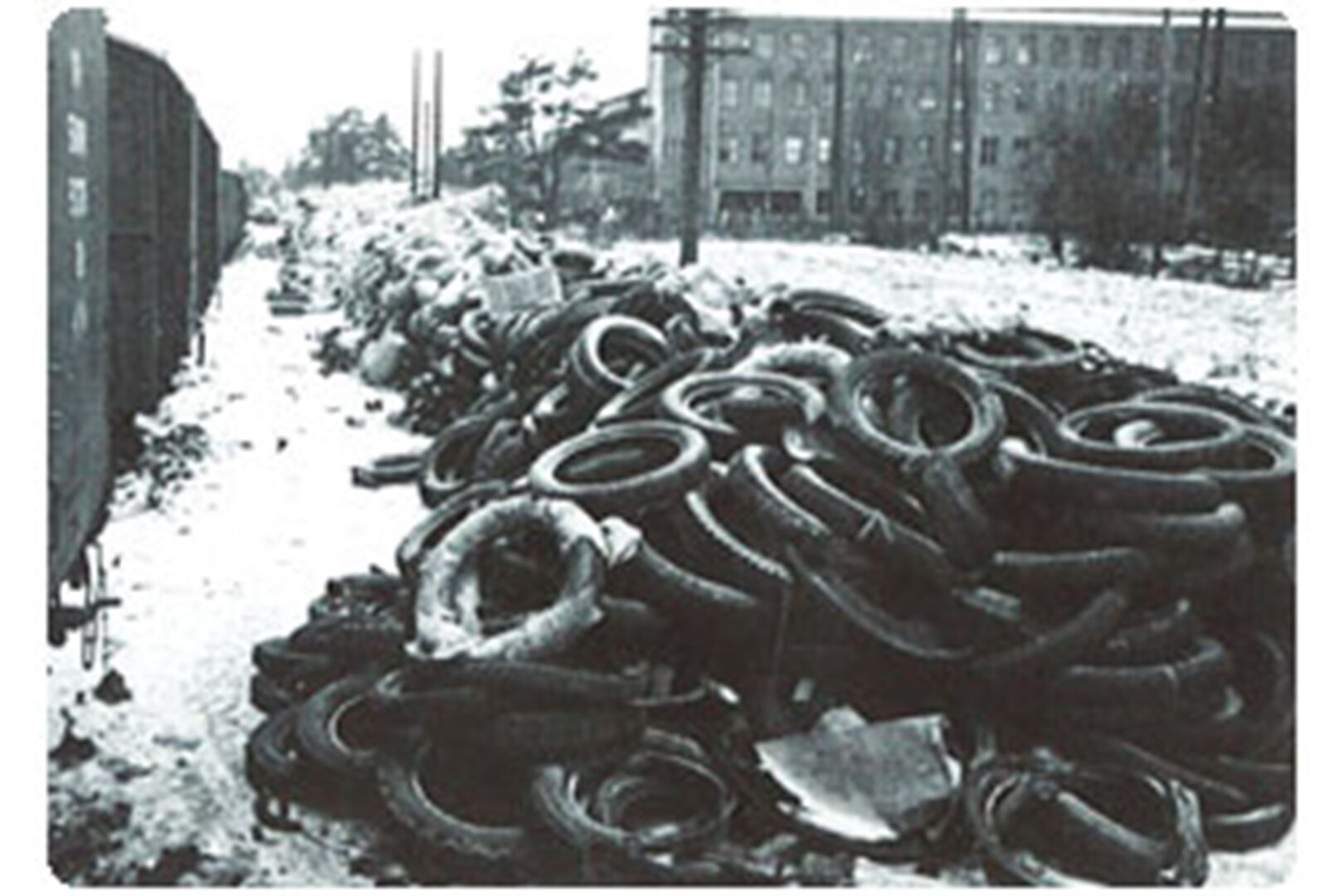

Recycled rubber or regenerate was manufactured from waste rubber. The nationwide collection campaigns produced good results, and the railway station at Nokia was filled with piles of tires. Regenerate was used more in bicycle tires than car tires.

In the midst of the war struggle, Gummitehdas had faith in the future. The construction of a new tire factory started in 1943 and production started after the war in 1946. Once the war ended, the factory could also meet the accumulated need for passenger car tires. In 1948, production increased by over one half, as 40,000 car tires were manufactured in Nokia.

Regenerate

In 1940, the price paid for recycled car tires was 2 Finnish Marks per kilogram; inner tubes were FIM 4.5 per kilogram. During the war years, new rubber products were only available for purchase against waste rubber.

Suomen Gummitehdas had a special regeneration plant for refining waste rubber. The work was rather challenging. “It is easier to turn an omelette into eggs with shells than to make rubber waste as good as raw rubber,” said manager Ensio Salmenkallio from the tire department.

Image: Rubber waste at Nokia railway station during the Continuation War.